At Tusheng, innovation is at the core of everything we do. Our dedicated R&D team continually develops advanced centrifuge technologies to meet evolving industry demands. From automated control systems to precision manufacturing, we integrate cutting-edge solutions to enhance performance, safety, and efficiency in every product.

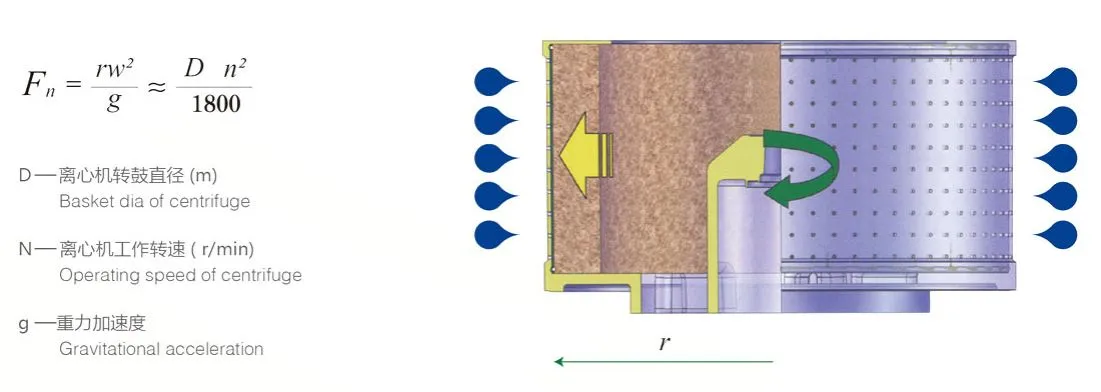

Separation factor is an important factor affecting effects of separation in a centrifuge.

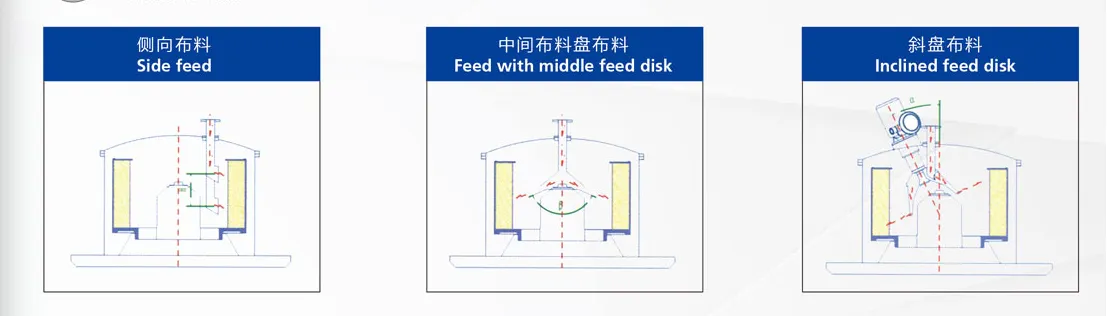

Inclined feed disk working principle:

The feed disk is driven by an independent motor and slurry isaccelerated

Feed disk rotating speed is adjustable, the feed disk has the samerotating direction as the drum; their angular velocities are basicallyequivalent, but there is a rotating speed difference; the inclinedfeed disk can make slurry from the feed disk evenly distributed inthe drum height direction.

Surrounding discharge ports of the feed disk is distributed in the formof sine curve after being projected onto the inner wall of drum.

Adjusting angle of feed pipe and changing the feed range can improvefeed balance. filter cake thickness is basically the same in the directionof drum height; for material with poor mobility, improving feed uniformity is of great significant to reduce the vibration.

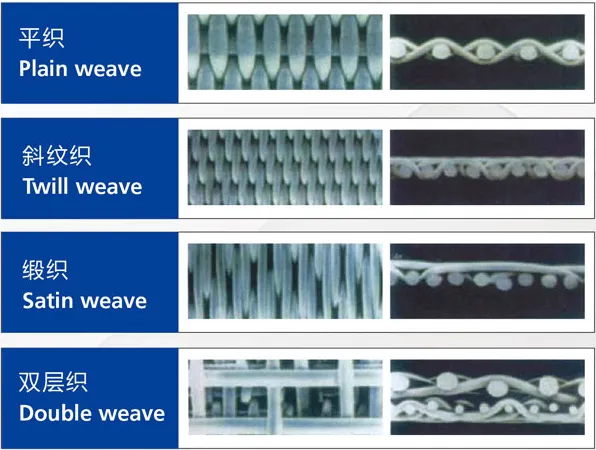

Filtration practice shows that life cycle of filter cloth is not determined by worn condition of filter cloth usualy but by the blocked or contaminated speed. Thus, how to prevent or releve the blockage of filter cloth and how to regenerate the blocked filter cloth is a signiicant issue for daily maintenance of filter cloth.

With the increasing times of filtration of filter cloth, it is inevitable for the fiter cloth to be blocked. However blockage of filter cloth notonly is related to its material and structure of filter cloth but also the particle makings and viscosity and other relevant factors of filteredmaterial. Reasonable selection of type (materials, weaving method) and mesh number of flter cloth is a relatively effective method torelieve blockage of filter cloth.

After filter cloth is used for a certain period and when blockage of filter cloth is not very serious, the filter cloth shall be cleaned withwashing device of centituge, and the cleaning eriod shall be determined in the oraclical application process. in normal case. thecleaning period shall not be more than 8 fitration cycles and for the specific material, the specially prepared cleaning agent for filtercloth can be used for cleaning (three-way conversion can be aranged on the sluicing pipe and the outlet of mother liquid. )After filter cloth is cleaned and when filtration performance stillis sianificantly reduced or fiter cloth is hardened, it shows that blockage of flter cloth is very serious and then the filter cloth needs to be taken down and to be cleaned after being soaked in medicacleaning gent.

Dearadation of filtration performance of filter cloth means extension of filtering and washina time and dearadation of washing elecand at the same time, it means the increase of moisture content of flter cake, reduction of production, instable product quallty andincrease of production costs. Thus, the formulation of corresponding reaeneration beriod and maintenance of filtration performance oifilter cloth are very important.

In separation process of most materials, the filter cake needs to be cleaned at the same time of dehydration to realize the requiredpurity of product. in separation process, there is not only moisture content index of f”ter cake but also the index of measuring purity oifilter cake. Thus, how to realize the washing requirement of filter cake in the shorter time and with fewer consumption of cleaning geniis very important for capacity quality and energy consumption and cost.

The materials to be separated are normally corrosive. So for safety,the parts in contact with these corosive materials must be anti-cor

rosive.

Common corrosion resistant steel: 304,321 316L, 904L,TA, 2205,2507 etc.

When there is determined application experience or corrosion data,cary out coupon test and aboratory vertication to ensure selectecmaterialmeet antl-corrosion requlrements.

Surface anti-corrosion treatment: PE lined, rubber lined, halar lined and F40.F46.PFA etc.Anti-corosion reguirements of sealing elements can not be neclected, material of sealing elements shall ensure prevention againstcorrosion from acids, alkali and solvents.

The customer shall forward the physical and chemical properties of the material and washing iquid (chemical properties and separa.tion temperature etc ) to the manufacturer so that it can make recommendations for centrifuge materials based on characteristics ofthe separation medium, and that the suitable seal ring, seal washer and filter cloth can be provided, thus ensuring anti-corrosiorrequirements on the centrifuge.

If the centrifuge works in the environment, where there are some explosive substances, the centrifuge should be explosion-proof. if thecentrifuge becomes really explosion -proof it should take a variety of measures in mechanical, electrical control and the accessories selection.

The following factors may result in hazards during selection, installation , operation and maintenance of centrifuge:

Prior to installation, the user should observe the installation requirements as indicated in the delivered documents. Pay attention for following factors :

There should be enough space between the centrifuge and equipment and other devices installed next to the centrifuge. Around the centrifuge.there must be a footpath no less than l m in width and above the centrifuge there must a space no less than 2m in height for mounting & dismounting and maintenance. When installing and positioning the electric control box, the hydraulic system, the nitrogen protection system, the space for mounting and dismounting should also be taken into account.The electric control box should be placed at a dry and ventilated place without corrosive gas, and it should be near the main uni(Separated

installation is allowed)

The on-site control button (operation platform) should be mounted beside the main unit to facilitate operation.The connection piping (feed pipe, drain pipe, wash pipe vent pipe, ClP pipe, nitrogen pipe, air compressor hose, wire cable, etcmust be the lexlble. The ioints should be sealed with insulation rinas, The machine should be earthed to avoid electricily leakaceFeeding pipeline and discharge pipeline should be sized as short as possible for avoidance of blocking. Hydraulic oil pipeline shouldbe sized as short as possible to reduce loss of pressure.The diameter of the external discharge pipe should not be smaller than that of the outer pipe and there should be no sharp bend orblockage on it. The pipeline should be laid at a height lower than that of the exit with a necessary height diference to ensure astraightway for the liquid discharge.Centrifuge feed pressure shall be kept at 0.5 bar Gas source pressure (used to drive the feeding and washing valves) shal not beless than 0.5Mpa, oil-water separator should be provided, and check should be made of the separator frequently, in particular whenair humidity is large to prevent moisture from entering the cylinder and control valve. Lubrication oll should be iniected into the oil foagenerator in the gas distrilbution device to reduce component wearing in the pneumatic system and operating resistance.The electric , pneumatic and liquid pipelines and wiring should be properly connected by electricians and mechanics for the runningand adiusting of the centrifuge, in accordance to the electric control schematic diagram and system configuration diagram.

The choosing of the filter cloth should meet the anticorrosion requirements, and appropriate filter cloth material such as polypropylene, polyester nylon, vinylon and cotton and other relevant materials should be chosen in accordance with the chemical properties of the separating material.The filter cloth mesh should be determined depending on the particle size of the separating material. Generally, the filter cloth mesh should be slightly larger than the particle size to beintercepted. At the beginning of the filtration, there will be a small quantity of small-sized particles penetrating the filter cloth.However when the intercepted larger particles accumulate and form a cake layer the penetrating phenomenon can be eliminated and the filtration efficiency will be improved.

Jiangsu Tusheng Centrifuge Manufacturing Co., Ltd. was formerly Zhangjiagang Yongtai Centrifuge Manufacturing Co., Ltd., which was established in 2003. It has a 20-year history and rich experience in the design and manufacturing of separation equipment. The company has been committed to the research and development, production and sales of dry centrifuges.

© 2025 Tusheng Centrifuge. All Rights Reserved.

Designed by AdmarV